Piping, industrial flares, thermal oxidizers: expertise for over 30 years

Eiffage Métal designs, manufactures, assembles and maintains industrial flare systems and thermal oxidizers. The company offers flare systems for the onshore/offshore oil & gas, gas storage, petrochemicals, water treatment (biogas), biomass, rail tank degassing, gas combustion units for LNG-powered ships, and mobile flares and thermal oxidizers sectors.

Eiffage Métal is also active in industrial piping, covering the entire production lifecycle: from detailed design, through manufacturing, to installation and commissioning, including all safety checks. We design piping systems for a wide range of sectors, including the petrochemical, pharmaceutical, food, energy and airport industries. These handle the transport of fluids such as process fluids, steam, water, gas, compressed air, nitrogen and more.

Our knowledge and experience help guarantee the performance of industrial installations, optimize production processes and ensure compliance with quality and safety standards.

-

Quality, Hygiene, Safety, Environment

- MASE – Safety, Health and Environment Management System.

- ISO 9001 – Quality

- ISO 14001 – Environment

- OHSAS 18001 – Safety

Factory Production Control Compliance

- EN 1090-1:2008 + A1:2011 EXC4

- EN 1090-2:2008 + A1:2011

Welding quality requirements

- EN ISO 3834-2:2006

-

- Welding qualifications according to ISO 9606-1

- QMOS (welding procedure qualification) according to ISO 15613 & ISO 15614-1

- DMOS (welding procedure description) according to ISO 15609

- NF EN ISO 25457 – General purpose flare system details

- Eurocodes and National Annexes.

Our achievements

- New or upgraded installations (maintenance)

- Recurring on-site partnership with installations and base facilities

- Turnkey projects: valves, equipment, piping, supports, connections, non-destructive testing, testing, painting

- Process or utility networks

- Biogas plants

- Design and manufacture of flares, on-board flares and thermal oxidizers

-

SIAAP Achères

SIAAP Achères

Three 2,500 Nm3/h biogas-fired thermal oxidizers.

-

Mabruck oil operation Libya

< class="name">Mabruck oil operation Libya

< class="name">Mabruck oil operation LibyaMaintenance work on two flares on the AL JURF offshore site.

-

TOTAL petrochemicals

TOTAL petrochemicals

Maintenance work on two 140 m propylene flares.

-

Lubrizol Oudalle

Lubrizol Oudalle

Maintenance work on a 45 m flare (flare tip and ancillary piping replacement).

-

International petroleum corp.

International petroleum corp.

Provision of a 1,375 Nm3/h petroleum gas-fired thermal oxidizer.

-

Atlantic Construction Sites

Atlantic Construction Sites

Supply and equipment of five Gas Combustion Units for LNG-propelled ships.

-

SOGEEFER, SDH

SOGEEFER, SDH

Provision of two 150 Nm3/h thermal oxidizers for degassing railway tanks.

-

INEOS Feluy

INEOS Feluy

Gas flare verticality tests, magneto-inductive controls, tension and lubrication monitoring for the guy wiring system.

-

Sonatrach

Sonatrach

Provision of a 225 Nm3/h biogas-fired oxidizer.

-

GRTGAZ

GRTGAZ

Supply and installation of two 5,000 Nm3/h mobile gas flares and a 1,000 Nm3/h mobile natural gas-fired oxidizer.

-

SBS Mourenx

SBS Mourenx

Provision of a 220 Nm3/h acrolein (propenal) oxidizer.

-

Berkes Crechy

Berkes Crechy

Provision of a 4,500 Nm3/h biomass flare tip.

-

Our business sectors

-

Industry

-

Culture / Luxury

-

Aerospace

-

Defense

Our expertise

-

- Cost, deadline and quality management

- Compliance with customer requirements

- Risk analysis

- Management and monitoring of partners and suppliers

- Supply chain tracking and traceability

- Perfect completion management

-

- Complex design and calculations

- Intervention and assembly methods adapted to each project

- Modeling and 3D scanning of existing structures

- Technical specifications

- Diagnosis of structures and works

-

- Production and processing

- Shaping structural steel parts

-

- Site supervision and coordination

- Compliance with safety, security and environmental regulations

- Adaptation (parts and methods) to the existing structure

- Lifting operations

- Assembly

Our expertise

-

Design

< class="name">Design

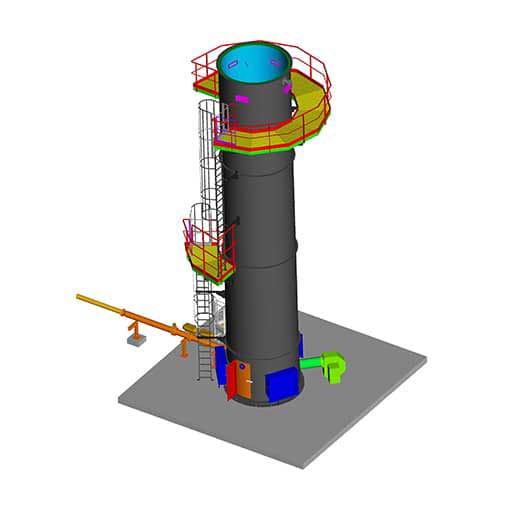

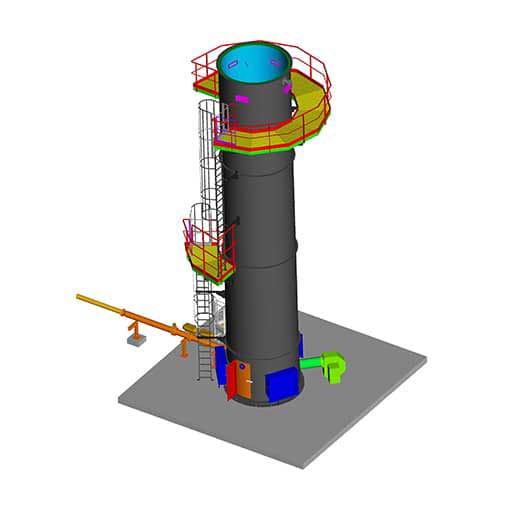

< class="name">DesignEiffage Métal designs, from the composition and flow of the gases, any system of torches (guyed torch, torch on derrick, stable auto torch, thermal oxidizers – with their equipment – flame detection, thermocouples, ignition station, torch nose, automation, etc.).

- From gas composition and flow: analysis, combustion, sizing, radiation, releases, noise

- Schematization: PID, functional analysis and Grafcet.

- Design office: stability calculations, realization of the overall plans and modeling of the torch.

-

Manufacturing

Manufacturing

The torch systems are manufactured in our Cuincy workshops, following procedures set up by a welding engineer (welding books, QMOS, DMOS, etc.) and defined control means (radiography, penetrant, PMI). Particular attention is paid to the choice of materials:

- Carbon steel (P265GH, API5L)

- Stainless steel (310S, 304L, 316L)

- Corten steel (marine environment)

-

Assembly

Assembly

Our teams of experts carry out the assembly work of the equipment.

- Blank assembly in our workshop in Cuincy.

- Assembly on site: transport, handling, connections, piping, electricity and automation.

- Commissioning: adjustments related to installations (fluids, electricity and automation) and training of staff on site.

-

maintenance

maintenance

We carry out strict inspections of the facilities to repair or replace one or more elements of the torch. This work is carried out during unit shutdowns.

Expertise: during scheduled shutdowns, we control the entire torch system (flame detection, ignition station and pilot, summer, guying systems, verticality, etc.) in order to establish a provisional report of the work to be carried out. It is also possible to conduct this expertise using a drone (our teams are trained to fly) if the torch must remain in operation.

Revamping: restoration and modification of torch systems in our workshop in Cuincy (checks, repairs, change of spare parts, reconditioning...).

L’ élément suivant est une vidéo Industrial flares and thermal oxidizers

A short-term requirement? Rent one of our mobile portable gas flare systems!

We offer you 2 mobile multigas flares for rental :

- One 160 Nm³/h flare system transportable by crate

- One 500 Nm³/h flare system on its trailer

Our strengths

-

Continuous improvement in quality certification and HSE performance

-

Expertise in project management with strong customer constraints

-

High production output and optimized delivery times

-

Plant location (access to the Rhine) to facilitate shipping